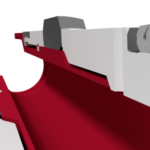

Designed to hold pressure from above or below and also in the event of sudden pressure reversals with double beveled Retractable Locking Dogs. The design incorporates an industry standard internal fishing profile and is run and pulled by standard wireline methods, the design in spring-free to eliminate the requirement for redress/replacement and also incorporates a hold down mechanism as standard t ensure operations can be carried out without premature release.

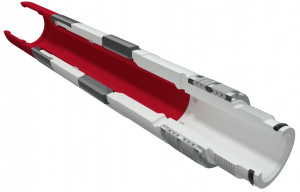

It is necessary to consider the Well environment and conditions when discussing the pressure rating of the packing unit, PTP offer Lock Mandrels in appropriate sizes and models up to 10,000 psi.

The PTP PAF Lock Mandrels are supplied in various Seal Material Configurations and materials to suit custom operational and environmental requirements.

The PAF Lock Mandrel provides reliability with a top No-Go for locating, landing and locking in the selected nipple at a pre-determined location for operation of subsurface flow controls and is ideal for Plugging under pressure. PTP offers a large variety of seal stacks from our standard seal stack (Molyglass/HNBR) to other combination elastomeric/non-elastomeric. As a standard, all ‘P-ALS’ Anchor Latch assemblies are supplied in materials conforming to NACE standard MR-0175 for sulfide stress cracking. Alternative materials are available upon request.